Before getting started, let’s understand the meaning of sustainability with its scope and necessity.

Sustainability is an art of doing things responsibly, efficiently in a disciplined way with a feeling of love for Mother Nature.

Ecologically it means the ability to meet the needs of the present without adversely affecting the ability of future generations to satisfy their needs.

Scope:

It starts from personal routines and extends to the surrounding, to society, to industries, to countries, and the world collectively. The scope of sustainability covers every constituent of the earth existing and growing naturally.

Necessity:

Precisely, sustainability is essential to protect the limited available natural resources from extensive and unwarranted exploitation to ensure the earth remains a habitable planet for the generations to come.

Sustainability in Textile at Faze Three Limited:

Through ideas, research, development, and innovation, Sustainability has always been an integral part of the various home textile manufacturing companies in India.

Right from the beginning, Faze Three Limited has always strived to conserve the naturally available resources by carrying out the business activities efficiently.

The senior management ensures that adequate policies are in place to educate each and every person associated with the Company with the basic knowledge about sustainability and its importance in the coming years.

The Company in the past few years has accelerated its efforts towards sustainability and pledges to make every effort to push it further in the coming years.

Some of the initiatives taken by the Company towards Sustainability in Textile Industry:

1. BCI Cotton yarn – Responsible sourcing:

450 metric tons per annum out of total 1800 metric tons i.e. 25% of the total cotton yarn sourced for consumption as raw material by the units is BCI cotton yarn.

The units aim to shift to BCI cotton yarn completely by 2021.

The company has registered itself on the BCI cotton platform to achieve its target for 100% BCI cotton consumption and to promote and create awareness about the need and benefits of BCI cotton between its stakeholders.

Sustainable impact:

The average water consumed in India for producing 1 kg of Cotton is 20000 liters. Taking an average of 5% water efficiency by BCI Cotton farmers in India, the consumption of 450 tons of BCI Cotton by the units has resulted in water savings by 450 million liters. Besides water footprint, responsible sourcing results in promotion of efficient farming practices leading to:

- Better soil health,

- Lesser use of synthetic fertilizers,

- Higher yield,

- Optimum use of land,

- Biodiversity enhancement

2. Recycled fiber and polyester yarn over virgin:

100% of the total polyester fiber consumed used as filler is recycled fiber.

The average recycled polyester fiber used is 250 metric tons per annum.

The units have started sourcing recycled yarn-dyed polyester and aim to increase this share to 60-70% of the total consumption by 2021.

The Company is exploring sourcing of recycled dope dyed polyester yarn and aims to increase its share by more than half of the total dope dyed yarn consumption by 2021.

The share of the recycled polyester yarn in Textile Industry by 2022 is aimed at 75% of the total consumption which is estimated at 1150 metric tons per annum including both yarn-dyed and dope dyed.

Sustainable impact:

- 250 tons of recycled polyester consumed by the units prevented approx.

- 1 million PET bottles annually from land filling and incineration.

- 1 million of recycled PET bottles cut down 180 metric tons CO2 emission from being released into the atmosphere.

3. Energy saving:

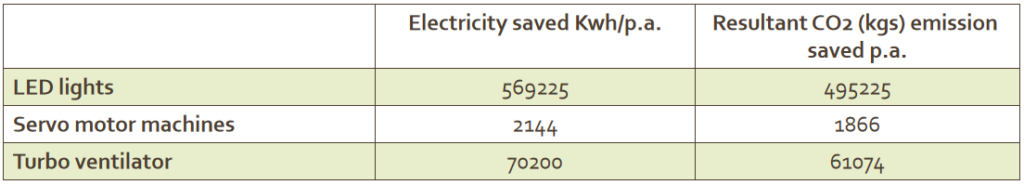

Installation of energy-saving LED lights (18-20 watts) replacing the fluorescent tube lights (40 watts) in the entire units.

Replacement of induction motor sewing machines with energy-efficient Servo Motor sewing machines. The RPM count increased from 3000 to 5000 resulting in increased efficiency, lower electricity consumption, reduction of thread wastage.

Setting up turbo ventilators instead of electrical blowers at the floor to suck out the heat paving way for better working conditions for the labor.

Electric 2-3 wheeler introduced for transporting goods within the unit, cutting down fuel combustion.

Sustainable impact:

4. Recyclable materials for packaging:

100% of the packaging materials sourced by the units are recyclable resulting in the cut-down of carbon footprints considerably.

In the year 2018-19, the units sourced 2140 metric tons of recyclable packaging materials including 2000 mt of biodegradable paper and cardboard, 130 mt of plastic poly bag, 10 mt of the plastic hanger, and others.

The single-piece packaging as well as the carton packaging are dimensional and designed in such a way that it results in optimum utilization of the container space thereby resulting in inefficient transportation.

0% of plastic waste in both units.

Sustainable impact:

- Elimination of land filling and incineration by plastic and other toxic waste materials.

- 830 mt of recyclable cardboard paper = Approx. 35000 trees saved annually

- Recycling of 1 kg of plastic saves on average 2.5 kg of CO2. By sourcing 130 mt of recyclable poly bags, about 325 mt of CO2 emission is saved annually.

5. Reforestation:

A considerable portion (approx 30,000 sqft) of the land surrounding the factory buildings of the units is dedicated to reforestation.

Hundreds of trees and bushes with green grass have been planted and maintained efficiently in the said portion.

Sustainable impact:

- 1 tree lessens approx. 22 kg of CO2 footprint annually.

- Approx. 25 metric tons of CO2 footprint mitigated annually with the help of reforestation by the units.